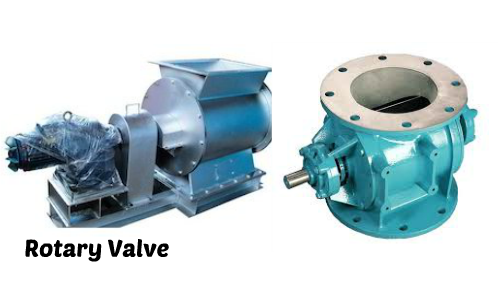

The Effects of Improperly Applied and Rotary Valve

Isolated spaces, while basic, are an imperative piece of certain material passing on and preparing tasks. Utilizing one erroneously can make hardware endure undue wear and work less proficiently. It can likewise prompt expanded expenses because of additional support and administrator working hours. In the most pessimistic scenario, it can make gear break or breakdown to the point that downtime is vital.

Wear-and-tear to the rotor, lodging, or both is one of the main sources of airtight chamber valve disappointment. Preparing rough materials makes total harm the surfaces inside the valve. Surface drag scraped spot happens when materials are caught between two surfaces moving in various ways. It can likewise be the aftereffect of any sort of surface-on-surface contact where rough materials are between the two planes. Pneumatic helped scraped area happens when turbulent air, or “pass up,” creates at the outlet port when utilizing a pneumatic passing on framework. This misled air can cause noteworthy loss of productivity and issues with material stream. This wayward air can likewise convey with it grating particles that can make superfluous harm valve segments.

Shree Techno Engineers is the best Rotary Valve Manufacturers in Ahmedabad. Choosing the Rotary valve that will enable your tasks to accomplish ideal proficiency is profoundly essential, so don’t surrender it over to risk. The Shree Techno Engineers can discover or create the ideal valve for your necessities. They likewise perform repairs on existing valves, and will give you fair answers about whether repair or substitution is the better choice in your circumstance.

Rotary valves are utilized as a part of an extensive variety of utilizations where there is a need to limit framework air misfortunes while exchanging material between vessels with contrasting weights. Rotary valves are utilized for vacuum or weight hoping to release nonstop stream of materials. It is offered in CI or steel or tempered steel material.

The essential capacity of a Rotary valve is to control the spill out of one chamber to another while keeping up a decent sealed area condition. The item is basically in dry powder or granular from.

Applications

Storehouse Discharge: The rotary valve set under the storehouse or residue accumulation framework is utilized to control the mass strong release.

Dose Control: By controlling the turn speed of the sealed area feeder, volumetric metering and dosing of granular solids is accomplished.

Pneumatic transportation: The isolated space mounted under a violent wind is utilized for releasing the tornado.